Bevel Gear Generator - SpiralOERLIKON

C28

Bevel Gear Generator - Spiral

OERLIKON

C28

Година на производство

2000

Состојба

Користено

Локација

Германија

Сликите прикажуваат

Прикажи карта

Податоци за машината

- Ознака на машината:

- Bevel Gear Generator - Spiral

- Произведувач:

- OERLIKON

- Модел:

- C28

- Година на производство:

- 2000

- Состојба:

- половен

Цена и локација

- Локација:

- , Германија

Повикајте

Детали за понудата

- ID на огласот:

- A18736361

- Референтен број:

- 1113-235023

- Ажурирање:

- последно на 13.05.2025

Опис

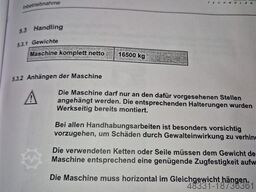

Technical details:

max. wheel diameter: 275 mm

gear width: 55 mm

max. module: 6,5

min. module: 1,5

Face Hobbing-Continious Process

Continuous process: The workpiece and tool (usually Spiron) rotate at the same time, and all teeth are created in one operation at the same time. Knife head has several knife groups (not arranged in a circle) Parallel tooth Conical tooth tip surface

Single Item procedure: The workpiece is stationary and the tool (usually Arcon) rotates and cuts a tooth by immersing the tool. Once a tooth is cut, the tool moves out of the tooth again, the workpiece divides by one tooth width and the next tooth is cut until all teeth are finished. Knife head has arranged all knives in a circular path. Conical tooth height Parallel tooth head surface

C28 can do both, wheel + pinion. However, a C28 must be “prepared” for the individual part procedure. I.e. direct measuring system + part gear brake, workpiece axis + license file for the production of individual parts.

Kodpov N Hilofx Adioll

*

max. wheel diameter: 275 mm

gear width: 55 mm

max. module: 6,5

min. module: 1,5

Face Hobbing-Continious Process

Continuous process: The workpiece and tool (usually Spiron) rotate at the same time, and all teeth are created in one operation at the same time. Knife head has several knife groups (not arranged in a circle) Parallel tooth Conical tooth tip surface

Single Item procedure: The workpiece is stationary and the tool (usually Arcon) rotates and cuts a tooth by immersing the tool. Once a tooth is cut, the tool moves out of the tooth again, the workpiece divides by one tooth width and the next tooth is cut until all teeth are finished. Knife head has arranged all knives in a circular path. Conical tooth height Parallel tooth head surface

C28 can do both, wheel + pinion. However, a C28 must be “prepared” for the individual part procedure. I.e. direct measuring system + part gear brake, workpiece axis + license file for the production of individual parts.

Kodpov N Hilofx Adioll

*

Документи

Доставувач

Забелешка: Регистрирајте се бесплатно или најавете се, за пристап до сите информации.

Регистриран од: 2013

Испрати барање

Телефон & Факс

+49 6406 ... огласи

Овие огласи исто така може да ве заинтересираат.

Аукција

Аукцијата завршена

Hessen

Hessen

1.407 km

OerlikonC28

Мал оглас

Cuggiono

Cuggiono

1.128 km

DOOSANVCF 850LSR

Мал оглас

București

București

469 km

KappRS 2003

Мал оглас

Burgoberbach

Burgoberbach

1.215 km

MikronVCE 600 PRO BJ 2012

Мал оглас

Lauchheim

Lauchheim

1.209 km

ZAYERKPU-4000 AR

Мал оглас

Hilden

Hilden

1.552 km

KLINGELNBERG-OERLIKONT60 A

Мал оглас

Германија

Германија

1.519 km

EMAGVSC 250 DS

Мал оглас

Wolkersdorf im Weinviertel

Wolkersdorf im Weinviertel

859 km

Aberlink /RenishawAzimuth

Мал оглас

OIching

OIching

1.101 km

HurcoVMX 64i

Мал оглас

Германија

Германија

1.302 km

PINACHOSC 200-42-1000

Вашиот оглас беше успешно избришан

Се случи грешка